Walnut Blasting Explained

We briefly touched on Walnut Blasting in our previous blog post, The Top 10 Engine Improvements For The 2.0 TFSI (EA113), but we want to dig deeper and really demonstrate what the process involves, how it benefits and whether it is suitable for your engine.

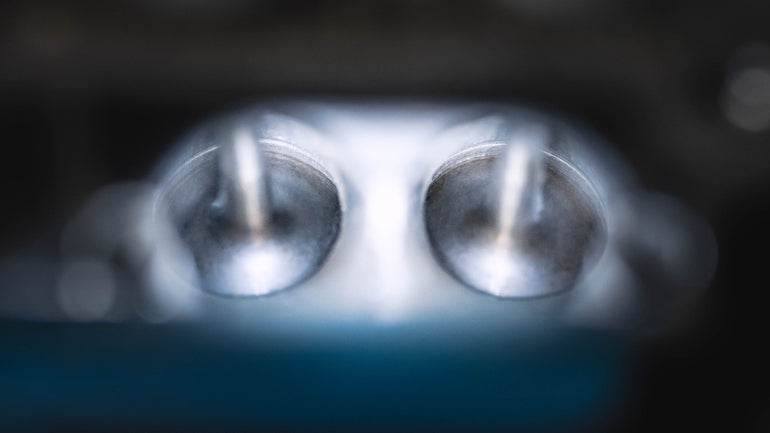

In short, walnut blasting is the process of removing carbon build up from the intake ports and valves with the use of compressed air and crushed walnut shells.

As you can see from the comparison image below, there is a remarkable difference with the before and after results.

It's a service we regularly carry out for customers with GDI (Gasoline Direct Injection) engines such as the 2.0 TFSI VW engine, often with injector cleaning. While the inlet manifold is off to gain access to the inlet ports, it wouldn't make sense to not get them cleaned.

What does Walnut Blasting involve exactly?

Walnut blasting involves 3 things. Crushed walnut shells, compressed air and a vacuum.

- The crushed walnut shells are a specific size based on their purpose and the machinery you are using. If the wrong sized walnuts are used, they will block your machine or not be abrasive enough to successfully lift the carbon from the inlet chamber and valves.

- Compressed air is used to carry the crushed walnut shells out of the tank down the tubing into the inlet port, however a high capacity and powered compressor is required to maintain a consistent flow of compressed air.

- Finally, the walnut blasting machine utilises a vacuum to remove the walnut shells and carbon from the inlet port and allows consistent flow of fresh walnut shells into the chamber.

Carbon deposits are released from the surfaces and are sucked into the vacuum, leaving the ports looking like new.

Why walnuts?

Walnut shells are a good medium, abrasive enough to lift carbon from a surface, but soft enough to not impact or damage the surface of the engines components such as the valves or the aluminium cylinder head. They are also a combustible material, so in the unlikely event that any go into the combustion chamber, it won't matter as it will burn off once the engine is running.

Understood, but why can't I just get a carbon clean service?

Any carbon cleaning process which involves feeding gas such as Hydrogen into the intake pipe won't make the slightest bit of difference to the carbon build-up on the intake valves/ports. Many people are mislead by companies selling £50 carbon cleans, or try to incentivise you by including it with a remap. Please don't confuse this with walnut blasting because it requires the physical removal of the intake manifold and other components to effectively remove the carbon deposits.

Why does carbon build up in the inlet chamber and on the valves in the first place?

One of the downsides to GDI is not having fuel pass through your inlet ports, which means oil vapours from the PCV system are not being 'washed' away by the fuel. The result of this is a tremendous amount of carbon build up in your inlet ports of your cylinder head, reducing the efficiency of your engine which means a reduction in power, fuel economy and a rough running engine.

Can I stop the carbon building up in the first place?

In a word, yes. However its not that simple. The ways in which carbon build up being prevented are just by-products of other engine modifications.

The best way to reduce the speed in which carbon builds up is to maintain a good level of servicing; good quality oil and oil filters are essential. Also, reducing the amount of short journeys where the engine isn't getting up to temperature would be of benefit.

Essentially to prevent it completely, a form of traditional port injection could be used, whether that is fitting a water/meth injection kit or retrofitting a port injection setup to work in conjunction with your GDI configuration, but nether of these would be fitted with the sole intention of preventing carbon build-up. They would be fitted to enhance your engine in other ways most often for highly tuned road or race vehicles.

You can mitigate the speed in which carbon does build up by fitting a catch can, reducing the amount of oil vapours entering the intake system.

I've got carbon on in my inlet ports and on my valves, so what?!

Ok, so your engine isn't going to seize, but it will not run efficiently with the amount of carbon build up we see on all GDI engines without walnut blasting having been carried out. Fuel efficiency and power are both sacrificed, not to mention poor running issues in some cases. If your engine is running poorly, it's going to be of benefit if you had the injectors cleaned and tested along with walnut blasting.

I want this doing, what engines can you do this on?

There is a wide range of engines we can carry out this service on.

A list of the most common engines we walnut blast are listed on our Specialist Services page, which is available here.If your engine is not listed, please get in touch and we may be able to provide a solution for you.

Hopefully this blog post has helped you understand more about the process so you can see how it is done and the importance of it.

If you are interested in this service, see the Specialist Services section of our website for pricing information.

If you have any further questions about walnut blasting, please do not hesitate to call us on: 0114 276 8193 or email us at: info@jbmperformance.co.uk